Selecting the appropriate hydraulic pump for your application requires careful consideration of several factors.

Here are some steps you can follow to determine the appropriate hydraulic pump for your application:

Determine the required flow rate: The flow rate is the volume of fluid that the pump can deliver per unit of time, typically measured in gallons per minute (GPM). Determine the required flow rate for your application based on the hydraulic system’s needs.

Determine the required pressure: The pressure is the force per unit area that the pump can generate, typically measured in pounds per square inch (PSI). Determine the required pressure for your application based on the hydraulic system’s needs.

Determine the required viscosity: The viscosity is the thickness or resistance of the fluid to flow, typically measured in centistokes (cSt). Determine the required viscosity for your application based on the hydraulic system’s needs.

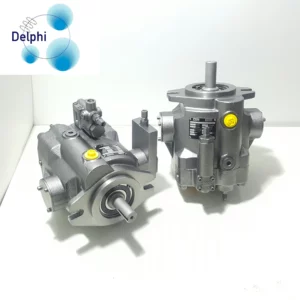

Consider the type of pump: There are several types of hydraulic pumps, including gear pumps, vane pumps, and piston pumps. Consider the advantages and disadvantages of each type of pump and select the one that best suits your application.

Consider the pump’s size and mounting requirements: Ensure that the pump’s size and mounting requirements are compatible with your application’s available space and mounting options.

Consult with an expert: Consult with a hydraulic system expert or a manufacturer’s representative to ensure that you select the appropriate hydraulic pump for your application.

By following these steps, you can determine the appropriate hydraulic pump for your application. parker hydraulic pump catalog It’s important to select the right pump to ensure that your hydraulic system operates efficiently and effectively.

What are the common mounting options for hydraulic pumps?

Hydraulic pumps can be mounted in a variety of ways, depending on the specific application and system requirements.

Here are some common mounting options for hydraulic pumps:

Foot mounting: Foot mounting is a common method of mounting hydraulic pumps. In this method, the pump is mounted to a flat surface using bolts through the pump’s base plate.

Flange mounting: Flange mounting is another common method of mounting hydraulic pumps. In this method, the pump is bolted to a flange on the hydraulic system’s reservoir or tank.

Saddle mounting: Saddle mounting is a method of mounting hydraulic pumps that involves securing the pump to a bracket or saddle that is attached to the hydraulic system’s frame or base.

Through-drive mounting: Through-drive mounting is a method of mounting hydraulic pumps that involves attaching the pump to the input shaft of a hydraulic motor.

Close-coupled mounting: Close-coupled mounting is a method of mounting hydraulic pumps that involves connecting the pump directly to the electric motor’s shaft, eliminating the need for a separate coupling.

Vertical mounting: Vertical mounting is a method of mounting hydraulic pumps in a vertical position, which can be useful for applications where space is limited.

Remote mounting: Remote mounting is a method of mounting hydraulic pumps away from the hydraulic system’s reservoir or tank, which can be useful for applications where space is limited or where noise and vibration need to be minimized.

These are just some common mounting options for hydraulic pumps. The appropriate mounting option will depend on the specific application and system requirements, and it’s important to consult with an expert or a manufacturer’s representative to ensure that the pump is mounted properly.

Leave a Reply